When it comes to shaping materials with precision, two big players in the manufacturing world are die sinking EDM and precision wire EDM. They might seem similar at first glance, but they each have their own set of strengths and ideal applications. In this article we’ll explore:

- What makes die sinking EDM a go-to choice for certain tasks

- What makes precision wire EDM stand out

- Tips on picking the right EDM technology for your project

Understanding die sinking EDM

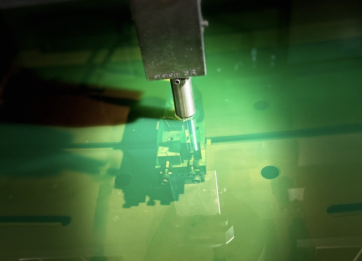

Die sinking EDM, often chosen for its versatility, has been a game-changer in precision manufacturing. Unlike traditional cutting methods, die sinking EDM doesn't make direct contact with the material, instead it uses electrical discharges between an intricately shaped electrode and the workpiece to mould the workpiece into the right shape.

Where die sinking EDM really shines is in its ability to craft detailed and complex geometries, particularly in hard-to-machine materials. The lack of direct contact between the tool and the workpiece minimises wear and tear, enhancing both the tool’s longevity and the consistency in repetitive tasks.

You'll often find die sinking EDM being used in industries where precision is non-negotiable. From creating intricate moulds for the automotive sector to engineering precise components for the medical and aerospace fields, die sinking EDM is an invaluable asset in high-stakes manufacturing tasks where detail, precision, and material integrity are key.

Exploring precision wire EDM

Precision wire EDM, another mainstay in the field of advanced manufacturing, offers its own set of unique benefits. Unlike die sinking EDM, precision wire EDM uses a continuously moving thin wire as an electrode. This wire, usually made of brass or stratified copper, cuts through the material with electrical discharges, producing fine, precise cuts.

Precision wire EDM is also renowned for its accuracy in creating intricate patterns and fine details. It excels in producing sharp corners, slender slots, and intricate contours, making it the ideal choice for components requiring extreme precision and smooth finishes.

This technology is a favourite in the tool and die industry for creating complex parts, such as punch and die combinations, and components with complex patterns. Its precision also makes it a go-to for industries that demand high accuracy, such as electronics and aerospace.

So, which one should you go for?

Die sinking EDM vs. precision wire EDM

When choosing between die sinking EDM and precision wire EDM, understanding their differences is key. Each technology has its particular strengths and ideal applications, let’s do an in depth comparison of each to help guide your decision:

Technical precision

Both technologies offer high precision, but they excel in different aspects. Die sinking EDM can achieve a depth accuracy of +/- 0.002 mm, ideal for 3D complex shapes and cavities.

Precision wire EDM excels in achieving a cutting precision of 0.001 mm, perfect for detailed 2D patterns and intricate contours.

Material compatibility

While both can handle a variety of materials, die sinking EDM is often chosen for harder materials like tungsten carbide, often used in mould making, where it can handle tough material due to its ability to shape without direct contact.

Precision wire EDM, with its fine wire and ability to work with a broader range of materials including softer metals, can maintain accuracy even on delicate materials without inducing stress or distortion.

Operational efficiency

In terms of speed, die sinking EDM might involve longer setup times, especially for custom electrodes. On average, creating a complex electrode can take several hours.

Precision wire EDM, however, with its continuous wire feed system, can be quicker for producing intricate patterns and shapes, with the ability to cut at speeds of up to 300mm²/min, depending on the material and thickness.

Cost considerations

The cost-effectiveness of each method varies based on the project. For instance, die sinking EDM can be more cost-intensive upfront; the electrode fabrication alone can account for up to 10-15% of the total operating cost, especially for unique or intricate designs.

Precision wire EDM, while efficient, can have a higher operating cost due to the constant need for new wire, with wire costs potentially contributing to 5-10% of total expenses.

Understanding these differences can help in choosing the right technology based on the specific requirements of your project, be it the complexity of the design, the type of material, or efficiency considerations.

Choosing the right technology for your needs

When deciding between die sinking EDM and precision wire EDM, several practical factors come into play:

Project specifics

If your project involves complex 3D geometries or deep cavities, die sinking EDM is likely your best bet. Its ability to achieve intricate shapes and depths is unparalleled. On the other hand, for projects requiring fine, detailed cuts, especially in 2D, precision wire EDM delivers the accuracy and finesse you need.

Production scale

Consider the scale of your operation. Die sinking EDM might be more cost-effective for large-scale production due to the durability and reusability of electrodes. For smaller-scale or varied production runs, the flexibility of precision wire EDM could offer greater efficiency and cost savings.

Volume and repetition

For large volumes of repetitive tasks, die sinking EDM can be more economical despite the initial cost of electrode fabrication. Precision wire EDM can be more efficient for smaller batches or prototypes where the speed of setup and versatility are crucial.

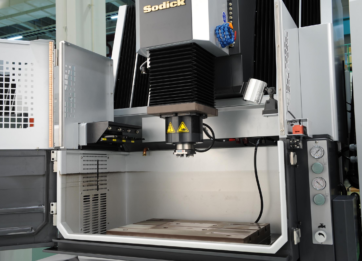

Take the lead in precision manufacturing with Sodick EU

With the insights into die sinking and precision wire EDM now in your arsenal, the next step is clear. Whether your project demands the intricate 3D capabilities of die sinking EDM or the meticulous detail of precision wire EDM, Sodick EU is your partner in navigating these choices.

Don't settle for less in your pursuit of manufacturing excellence. Let Sodick EU help you realise your most ambitious manufacturing visions, transforming them into tangible, cutting-edge realities.

It's time to experience the pinnacle of precision engineering. Reach out to Sodick EU today and take the first step towards redefining what's possible in your manufacturing project.